Serialization

Faced with demands to facilitate greater supply chain transparency for your customers, you need to ensure your coding is correct, compliant, and cost-effective. You also need to meet increasing requests to support digital marketing through specially coded packaging. Usually, this has meant using pre-printed materials, printer-based memory cards, or buying costly real-time controllers, thereby limiting such campaigns to a few lines. You need a more intelligent solution that can do this for you at scale.

Markem-Imaje's solution

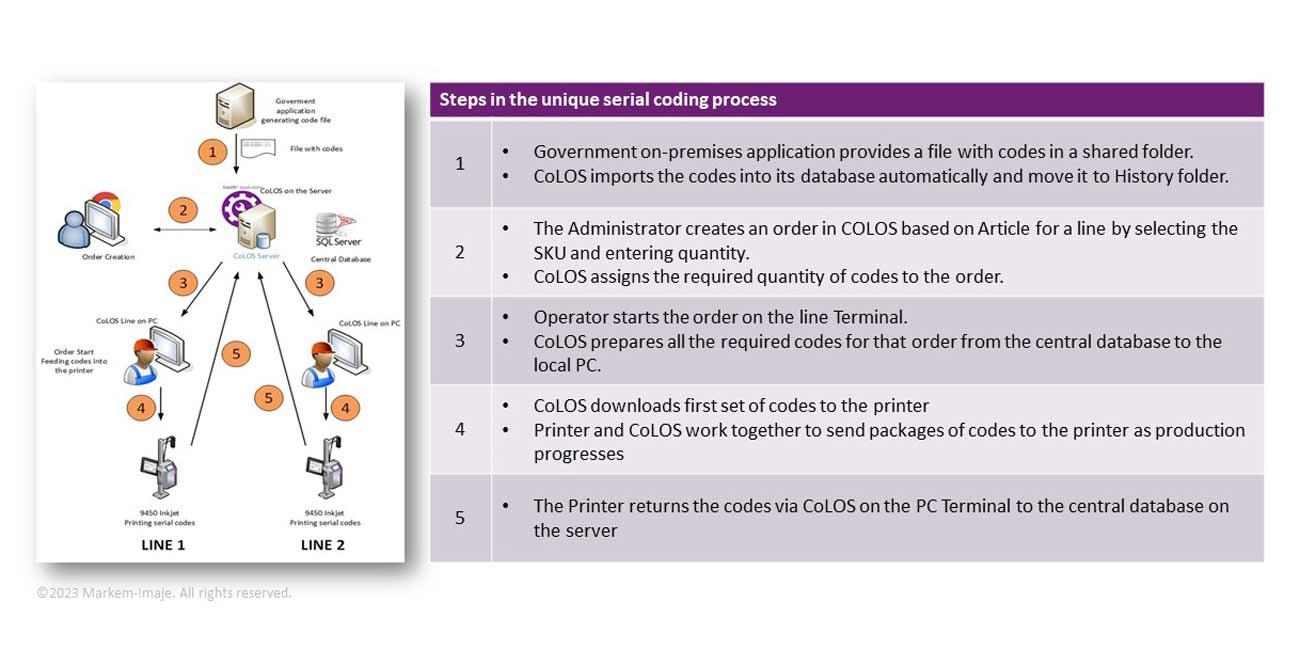

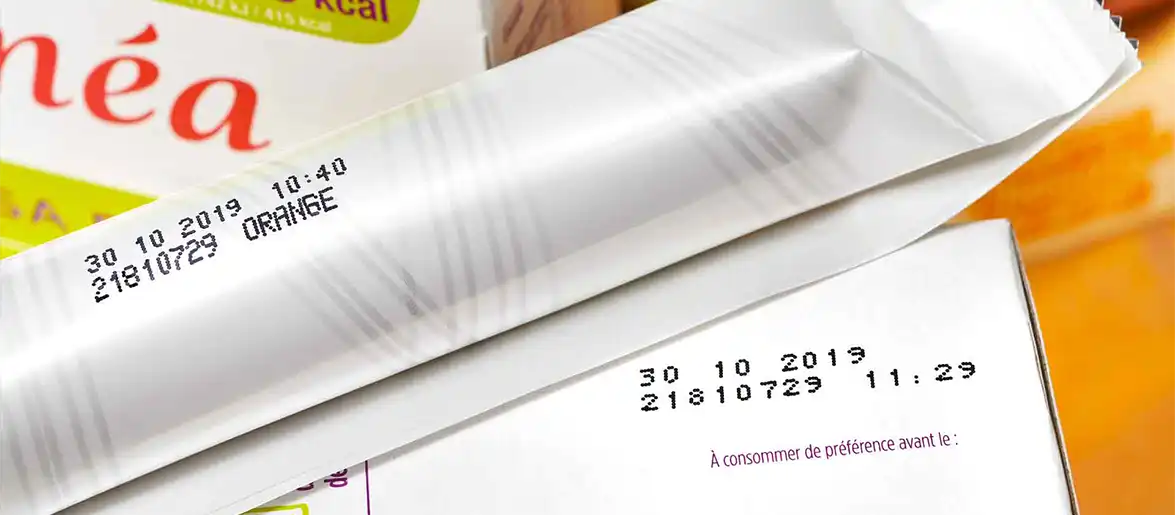

Our serialization solution, part of the Packaging Intelligence offer, makes it easier to use packaging to run promotions by printing unique codes on demand, even at high speeds. Our market-leading information management system, CoLOS ®, calls up previously generated codes from level four central servers or can generate the codes if required. The CoLOS ® system can offer complete code management and vision verification, a common requirement in digital tax projects.

In high-speed serialization applications, the data is sent in batches into the printer queue, so the real-time element is now handled at the printer level.

Markem-Imaje has both software capabilities and extensive experience in applying codes at high speed on many types of products. This lets us offer a complete turn-key solution from software to hardware.

Our serialization solution and full-stack capabilities can be deployed rapidly on any line, site, or enterprise in any region. Our software is configurable for unbeatable ease of implementation and speed to accommodate changing demands and meet regulatory compliance.

Our solution also helps ensure product compliance and easily integrates with the rest of our best-in-class equipment and third-party information systems and hardware.

Digital tax stamp application example

Features

- Create unique product identifiers, automate pallet labeling, and aggregate every packaging level for seamless traceability.

- Provide site-level master data, serial number management, event reporting, and offline serialization packing operations.

- Establish enterprise-level connectivity with comprehensive track-and-trace and compliance integrations.

- Application of unique codes to each and every product at full line speeds, ensuring flexibility for both on-demand and ‘always-on’ promotion.

- Storage of used codes for future reference together with ERP article information.

- Automatic verification and accurate processing of information printed on your products.

- Beyond standard functionality, full implementation of control processes, interfaces, or business logic is provided via the optional CoLOS ® Application Toolkit.

- Real-time reporting is also available as an option.

- Robust two-way communication with government tax code management systems.

Benefits

- No time wasted loading printer-based memory cards or installing expensive real-time controllers with associated hardware and software.

- No need to wait for, and spend time, loading pre-printed packaging materials.

- Seamless integration with limited impact, if any, on production rates.

- Ability to use generic packaging for digital marketing initiatives thus avoiding the need to forecast, and possibly over-order, pre-printed campaign-specific packaging.

- Helps create an open dialogue with consumers through mobile marketing activations on products with unique tracking codes.

- Fewer batch-related recalls thereby protecting your brand’s reputation.

- Improved compliance, minimizing retailer fines and/or delivery rejections.

Andreas Wehl – Head of Packaging Innovation and Cosmetics @ Töpfer

![]()

“In conjunction with our system, we ensure that we can send brand, item number, batch number, and more to our marking systems without errors. “

#CIJ

Andrea Boccolini – VFFS Technical Sales Support Manager @ IMA Ilapak

![]()

“Our machines are exported around the globe: IMA IIapak has always found Markem-Imaje to be an excellent partner capable of supporting our clients in every part of the world with widespread support and prompt service in the supply of spare parts”.“

#TTO #OEM

Xavier Bossard – Operations, Digital and Logistics Project Manager at Bioplants @ Bioplants

![]()

“The Markem-Imaje solution proposed to Bioplants was interesting because we could choose the criteria we needed: Before that, we were using a labeler, so one consumable item was created every time we labeled a package. Today we use hot melt ink directly projected on the cardboard allows us to add traceability to the packages, which we did not have before.”“

#TouchDry #HighResolutionInkjet

Nicola Marchesin – IT Manager @ Mebra Plastik

![]()

“This (CoLOS) has allowed us to be much more efficient, reducing line equipment times and making it possible to implement new solutions such as automated metrics, fewer ink types, and less waste thanks to more ecological containers and less energy consumption.” “

#CoLOS #SoftwareSolutions